Train new technicians faster and ensure all technicians troubleshoot issues as experts, even outside their skill set and work area.

When troubleshooting issues in advanced machines, the goal is not only arriving at the true diagnosis but also a desire to do so as efficiently as possible.

What we do

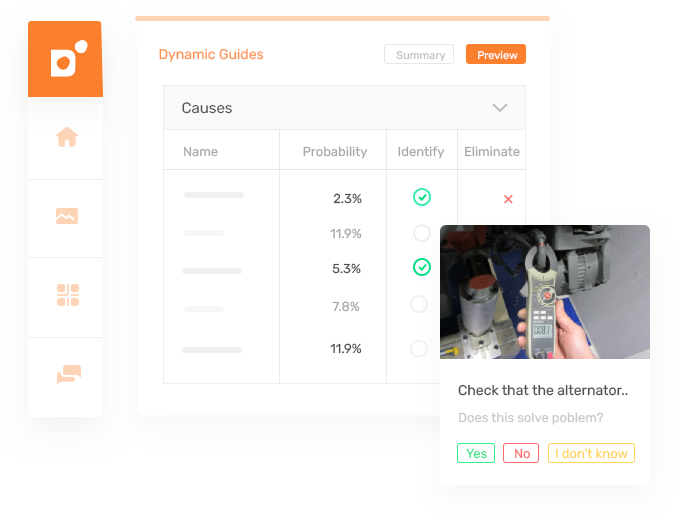

For 20 years we have helped service organizations capture expert troubleshooting knowledge using causes, probabilities, actions, questions, cost and time to ensure the most efficient troubleshooting experience

Reduce troubleshooting time

Fix issues on the

first visit

Instantly transfer skills to new employees

Use fewer spare parts

Key features

Reduced time spent troubleshooting

Using Dezide allows new technicians to quickly and precisely identify the root cause of an issue. The platform guides the technician through narrowing down the possible causes. By providing technicians with a step-by-step approach to troubleshooting, Dezide helps them quickly identify the issue and take corrective action. This saves time, increases efficiency, and reduces the amount of trial and error required when using traditional troubleshooting methods.

Improved training of new technicians

Recruiting and training are rising problems. The 20-year tech is a thing of the past. Most service organizations now expect to get 3-4 years from a new technician before he churns. We must ensure those techs are as productive as possible during those 3-4 years. Despite that level of churn, the tech still needs to feel confident that he can access tools that reassure him that he can appear professional to the customer and strengthen the customer relationship. The only way to ensure this is to enable the instant transfer of skills from the experts to the new generations - or from experts in one field to another.

What is efficiency in troubleshooting?

The fastest solution? The highest probability solution?

The cheapest solution?

Efficiency is the relationship between the likelihood of a cause, the time and cost of its related solution, and how costly it is to collect additional information about its likelihood.

That's exactly what Dezide does:

Dezide uses bayesian networks to provide technicians with a logical and systematic way of diagnosing and resolving technical problems quickly and accurately. Specifically, Dezide guides technicians through a step-by-step process of asking questions and gathering data to arrive at a solution. This allows technicians to quickly identify the problem, diagnose it, and provide the necessary solution.

But, how can you measure improvement in efficiency? How can you optimize your service organization by reducing troubleshooting time, increasing first-time fix rates, reducing spare parts consumption, and quickly transferring skills to new employees?

Ulrik Henriksen

Head of Diagnostics at Siemens Gamesa Renewable Energy

"We have proven that our technicians can solve complex problems up to 70% faster using Dezides AI-powered troubleshooting technology combined with our technical expert knowledge."

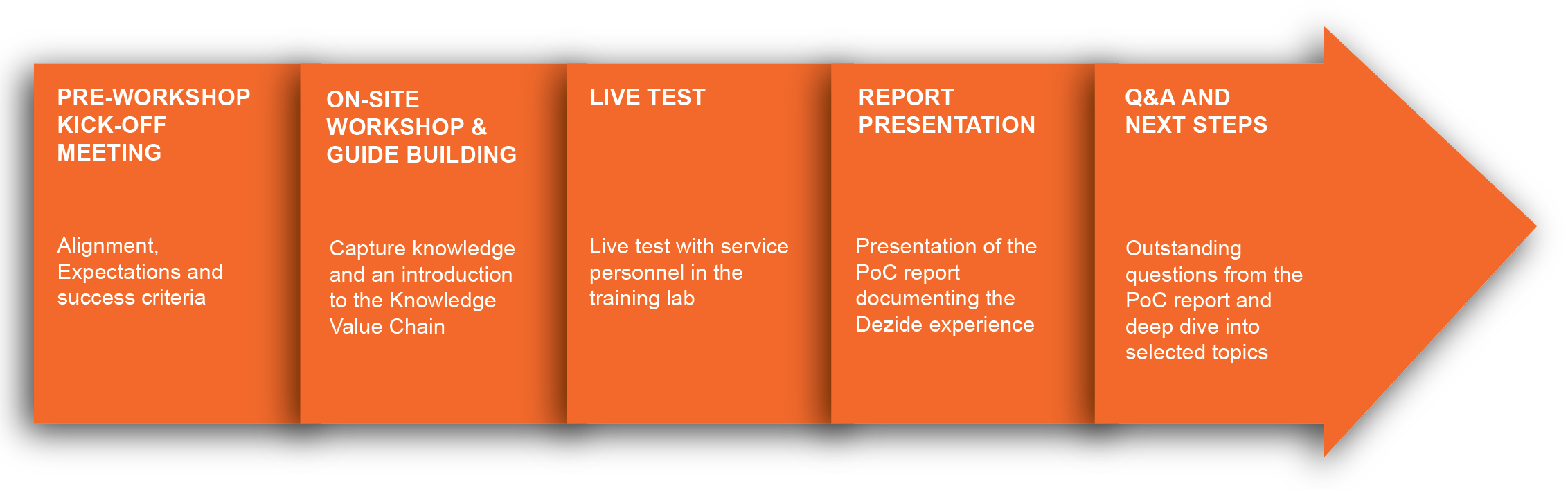

The best way to learn more about Dezide is through our 1-week Proof of Concept

An opportunity to experience what Dezide can do, and you will get concrete numbers for your business case. We will have technicians of varying skill levels troubleshoot errors of low, medium, and high complexity and track the results, which we will compare to the current state of efficiency in your service organization. In addition, you will experience first-hand how machine and contextual data can be used at runtime in the troubleshooting experience and see all the benefits of automated data evaluation.

Our PoC is designed to give you a personalized experience. Our dedicated Dezide implementation specialist will take you through the basics of how to best organize and structure your knowledge base. It is not the goal of the PoC to teach you everything there is to know about Dezide but rather to show you how expert troubleshooting knowledge is captured and how the system uses that knowledge for troubleshooting as efficiently as possible.

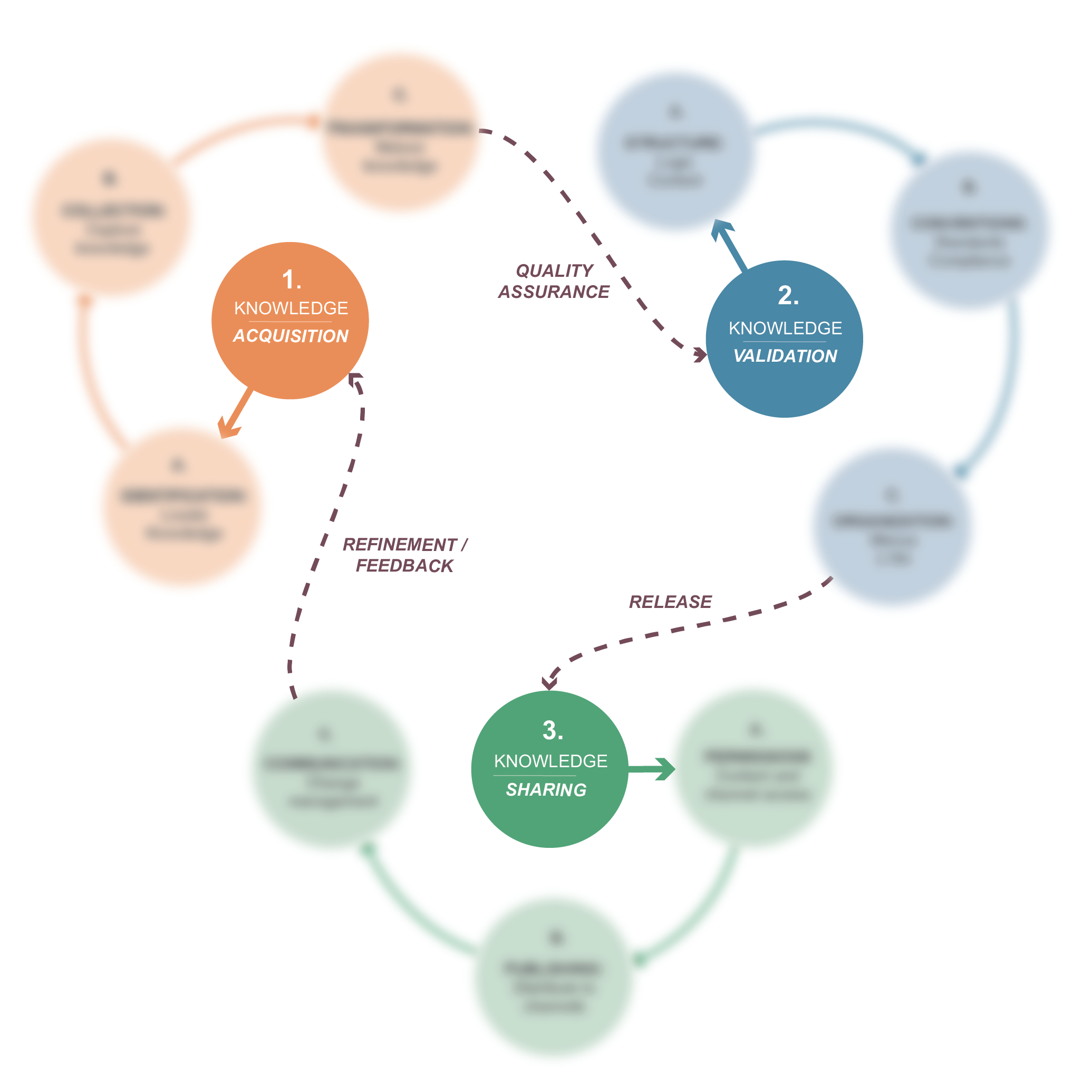

The Knowledge Value Chain

During the PoC we will also touch upon the very important topic of how to establish the organizational processes required for building and maintaining a high-quality knowledge base.

Through more than 20 years of experience, we have collected and described what we believe is the best approach to acquire, validate and share the technical troubleshooting knowledge in service organizations and distribute it in the best possible format to the end-users.

We call this the Dezide Knowledge Value Chain (KVC) as it relates to efficient guided trouble- shooting. The KVC is an integral part of the Dezide Implementation Framework that we use to support change management processes for the successful deployment of our software. As such, The KVC is Dezide’s process for building the best possible knowledge base using a set of practices that, when combined, results in a knowledge base that supports your service engineers on-site to solve problems in advanced products as quickly as possible. All while coming across as top professionals ensuring high customer satisfaction and long-lasting relationships.

Dezide Knowledge Value Chain

What kind of results should we expect from the 1 week PoC?

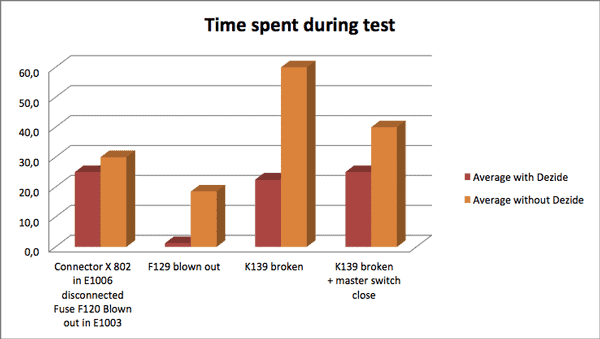

Rigorous testing were performed in the factory where several errors were introduced into an excavator, and the engineers should find and fix these errors with and without using the Dezide tool. On selected errors like “Relay broken” and “Fuse blown out” the troubleshooting time was reduced by an average of 60%.

Through tests, certain common errors were introduced into a wind turbine in the test facility. Two teams of technicians were assigned to resolve the problem. The first team contained only junior techs using the Dezide troubleshooting software, and the other team included only very skilled senior engineers with many years of experience.

The senior engineers resolved the problem in more than one hour. The junior technicians fixed the problem using the troubleshooting system in less than 15 minutes. Siemens Gamesa expects the troubleshooter to help them realize 70% for all highly complex issues and around 40% for the basic problems of average difficulty.